Description

Titanium

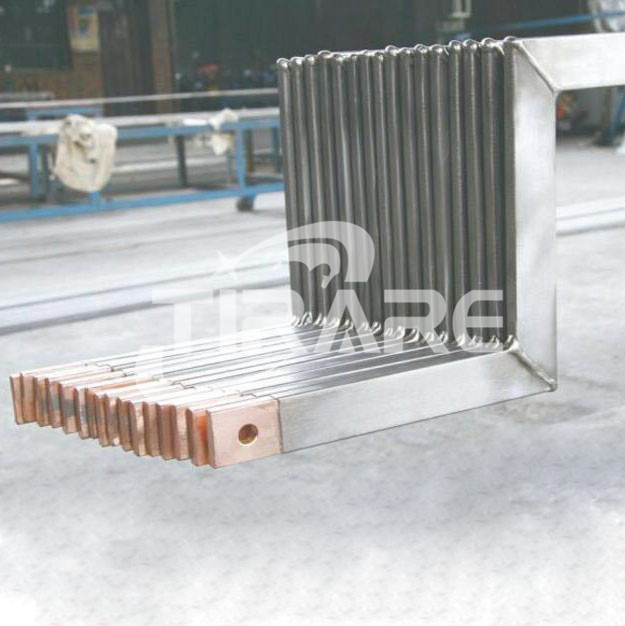

clad copper busbar

Substratum material: copper T1,T2, TU1 TU2, aluminum AL etc.

Cladding material: titanium Ti, Zr, Nickel Ni, Tantalum, etc.

Cladding layer thickness: conventional 1.0 ~2.5 mm

Reference standard: GB/T 12769-2003

Main cross-section shape and size range (mm) :

Rectangular width (20 ~ 150) x thickness (6 ~30)

Circle Φ (8 ~ 50)

Square model revised (10 ~ 30)

Silk material Φ (2.0 ~ 8.0)

40*10*L (Ti thickness:1.0mm)

Specific details will be according to drawing you provide

Applications:

In electric power distribution, a busbar (also bus bar, and sometimes misspelled as buss bar or busbar) is a metallic strip or bar, typically housed inside switchgear, panel boards, and bussway enclosures for local high current power distribution. They are also used to connect high voltage equipment at electrical switchyards, and low voltage equipment in battery banks. They are generally uninsulated, and have sufficient stiffness to be supported in air by insulated pillars. These features allow sufficient cooling of the conductors, and the ability to tap in at various points without creating a new joint.

corrosion condition of conductive body, such as electrochemical, electroplating, electrolysis, hydrometallurgy, PCB line, electric chemical industry, water treatment, ocean engineering, etc.

Advantages:

1. Effectively control the ratio of anode to cathode.

2. The anodic solubility is good and there is less anode slime.

3. The anode material can be easily loaded or replenished.

4. The anode material is completely used, saving energy consumption.

5. Titanium-clad copper features: It can not only ensure the original conductive properties of copper, but also protects the copper from corrosion by using titanium cover, and greatly reduces the electroplating and plating solution contamination.