Description

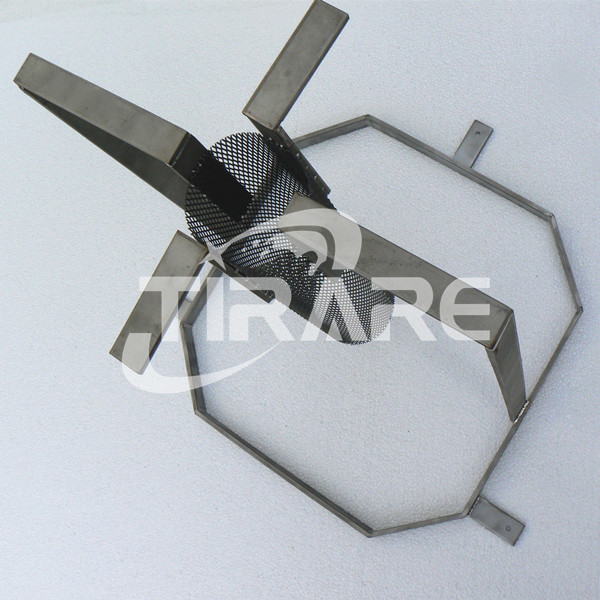

Titanium jig

Grade: Gr1, Gr2

Standard: ASTM B265, ASTM B348

Application: electroplating

Grade

Basis %

Impurity content % (≤)

Ta

Nb

Fe

Si

Ni

W

Mo

Ti

Nb

O

C

H

N

Gr1

Allowance

-

0.005

0.005

0.002

0.01

0.01

0.002

0.05

0.02

0.01

0.002

0.005

Gr2

Allowance

-

0.03

0.02

0.005

0.04

0.03

0.005

0.1

0.03

0.02

0.005

0.025

Requirement for titanium jig:

Electropolishing is, in principle a reversal of the electroplating process. Metal is removed by applying a dc current to the anodically connected work piece submerged in a special acid electrolyte. Removal takes place without inducing stress and preferentially affects the surface micro-roughness. The surface becomes smooth and bright, with burrs, edges and corners being removed preferentially.

The results can be repeated with a

high degree of precision so that components with tight tolerances can also be

treated in safety.

The use of titanium jigs is advised over copper or brass jigs with bronze

contacts since they will have limited life. The jigs should be of adequate size

in order to carry the high currents employed. Our jigs are perfectly designed

,developed,fabricated for Electropolishing applications.

The following details are required while enquiry/order :

(a) Tank Size

(b) Solution Depth

(c) Busbar Size

(d) Distance between Busbar and Solution level

(e) Physical sample components