Description

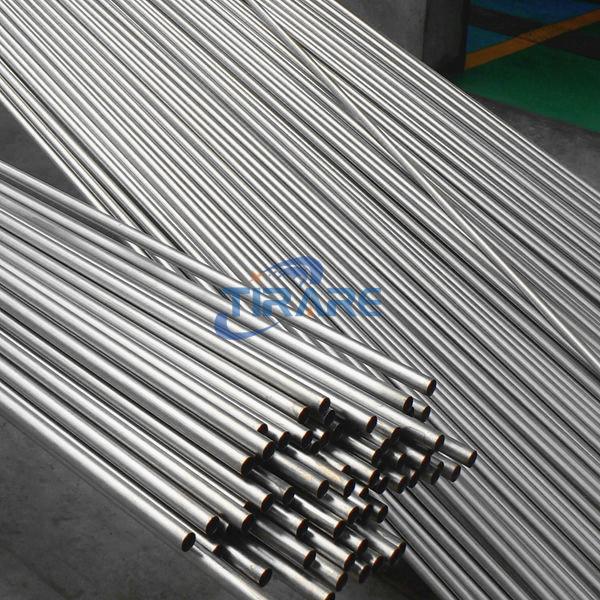

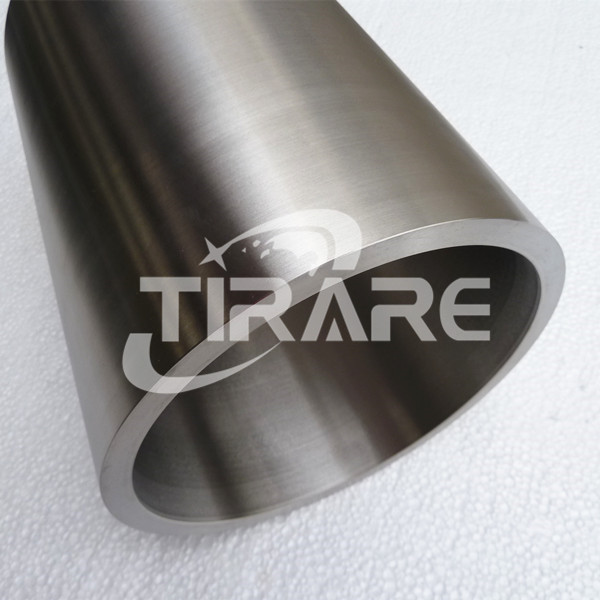

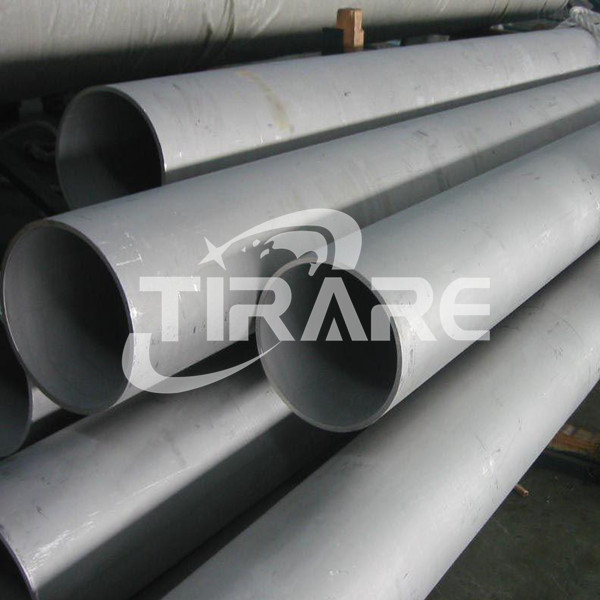

Titanium tubes for heat exchanger

Specifications:

Grades: Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr7 (Ti-0.12-0.25Pd), Gr9 (Ti-3Al-2.5V), Gr12(Ti-0.3Mo-0.8Ni), etc.

Standards: ASTM 337, ASTM B338, ASTM B861, ASTM B862, ASME SB337, ASME SB338, ASME SB861, ASME SB862, etc.

Dimension:

Diameter: Φ4-219mm

Wall thickness: 0.2~10mm

Length: within 15meters per piece

Commercial condition: annealed

Advantages:

With advantages of light weight, high strength and excellent mechanical properties, titanium tube is widely used in heat exchange equipment, such as heat exchanger coil, heat exchanger, serpentine tubular heat exchanger, condenser, evaporator, electroplating line and transportation piping, etc. Titanium tubes are used as working units in nuclear power industry.

Applications:

Car body trees, golf clubs, heat exchangers, hydraulic lines, wheelchairs, chemical plants, oil and gas production, tennis rackets, lacrosse sticks, drive shaft tunnel supports, exhaust tubing, wheelie bars, suppressors, heat exchangers.

Applications of typical titanium Gr1,Gr2, Gr9

Gr2- Titanium is said to have unlimited lifecycle use. Grade 2 titanium pipe is mostly used in chemical processing due to titanium’s ultra corrosion resistance. Titanium spools are created for chemical processing and all pieces such as flanges and valves are available to complete the assembly.

Gr 2 Titanium tubing-Titanium tubes are typically used in commercial heat exchangers in grade 2.

Gr9- Titanium tubes are commonly used in aerospace hydraulic lines in grade 9. The motorsports, sports equipment and bicycle markets have also found grade 9 very beneficial to their applications because of the light-weight and strength of titanium.

Any mass that has to be moved can benefit from the reduced weight that these tubes allow, giving quicker acceleration and deceleration. This gain is seen in sports shafts like golf and lacrosse. Exhaust tubing is a good application for motorcycles where the heat may be less than 800 degrees. Auto racing headers are still being figured out as they see more than 1000 degrees, which is above the normal operating range of titanium.

Quality Guarantee:

All products will be manufactured strictly according to ISO9001:2008 Quality Management system. Mill Test will be provided, we could also provide Test Report released by Third Party(Northwest Non-ferrous Metal Institute or other you appointed)